9mm Ammo Terminology

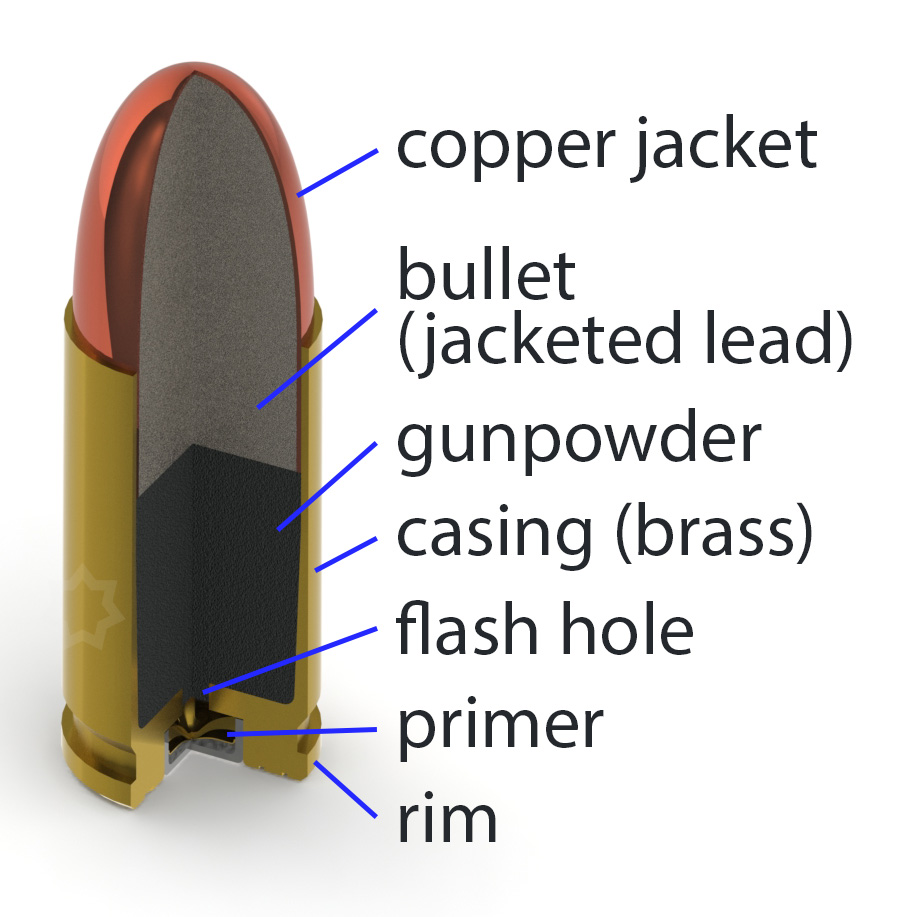

A cartridge (or round) of ammo includes the following components:

The casing, also known as the case, is filled with gunpowder. The base of the casing has a rim that allows the extractor mechanism on the firearm to grip the casing to expel it from the chamber after it is fired. In slang the spent casing is sometimes called a shell, not to be confused with shotgun shells. The most common material for casing construction is brass. Steel is sometimes used in lower cost ammo. These plated steel casings are a niche market and suffer from a reputation of lower reliability due to less favorable material properties compared to brass. Brass casings can be reloaded (‘hand loading’) while steel casings cannot.

The primer is at the base of the casing. This is the ignition device, consisting of a small charge of impact-sensitive chemical. When struck with sufficient force the primer ignites the gunpowder via the flash hole. If the ammo is designed to be struck in the middle, it is called ‘centerfire’. All calibers mentioned above are ‘centerfire’ except 22LR which is a ‘rimfire’ cartridge designed to be struck on the outer perimeter of the cartridge to ignite the primer.

The gunpowder is the propellant. When ignited, the explosion produces combustion gas that expands rapidly and forces the bullet to separate from the casing and to exit the barrel at high speed. Firing a standard 9mm caliber creates up to 35,000 psi maximum pressure upon detonation. The hot gases escape from the end of the barrel as soon as the bullet exits the barrel. This is called muzzle flash.

The bullet is the projectile portion of the ammo that is expelled through the gun barrel by the expanding gas. Some people mistakenly call the whole cartridge a bullet. By far the most common bullet material is lead. Other materials include copper, copper alloys, plastic, and rubber. Steel core bullets can pierce armor and can result in massive ricochet so they have been illegal in the U.S. since 1986. In most cases a lead bullet is partially or fully jacketed with brass or copper, and less commonly with plastic or zinc. The shape and material of the bullet influences its aerodynamic flight, its ability to penetrate through materials, and its ability to spread damage along its path through materials.

A close-up of the primer assembly is shown below. When firing a gun, the primer is impacted by the gun's striker. This dents the metal cup and detonates the shock-sensitive primer mix on the anvil. A foil disc keeps the primer mix in place and it disintegrates during detonation.

Next Topic: 9mm Ammo Types